Introduction

Imagine working in a factory with dim, flickering lights that cast shadows everywhere, making it difficult to focus on the task at hand. Now imagine the same factory, but this time illuminated with bright, well-placed lighting, making everything clear, comfortable, and safe to work on. The difference is profound and speaks directly to how factory lighting affects manufacturing productivity.

Factory lighting goes beyond simply illuminating a workspace; it plays a critical role in shaping the entire working environment, influencing everything from productivity levels to safety standards. In this article, we’ll explore how effective lighting impacts productivity, safety, quality, and energy efficiency, and how selecting the right type of lighting can create a better, more productive workplace.

The Importance of Factory Lighting on Productivity

Lighting and Worker Efficiency

Proper factory lighting directly impacts the efficiency of workers. Good lighting reduces eye strain and fatigue, helping workers focus on their tasks without feeling drained or distracted. When workers can see clearly, they are less likely to make mistakes, and they can complete tasks faster. Poor lighting, on the other hand, can slow down work, as employees struggle to see details or, in some cases, wait for better lighting to perform certain tasks accurately.

In manufacturing, where tasks are often repetitive and require high precision, lighting can make all the difference. Consider the example of an assembly line worker assembling small electronic parts. Under inadequate lighting, they may struggle to see tiny components, leading to longer assembly times and a higher risk of mistakes. By simply improving the lighting, companies can boost productivity without increasing workload or adding extra resources.

Mental Well-being and Productivity

Lighting also affects workers’ mental well-being, which indirectly influences productivity. Bright, natural lighting creates a more pleasant work environment, reducing stress and anxiety. Exposure to sufficient lighting, especially natural light, has been linked to increased levels of serotonin, a mood-boosting hormone. Workers who feel comfortable and less stressed are more likely to stay engaged, work effectively, and experience job satisfaction, all of which are critical factors in maintaining high productivity levels.

Safety and Accident Prevention

Lighting for Hazard Detection

In a factory setting, poor lighting can contribute to accidents, and even a minor incident can disrupt productivity and lead to costly downtime. With effective lighting, workers can better detect potential hazards, such as spills, obstacles, or equipment malfunctions. For instance, in factories with heavy machinery, appropriate lighting allows operators to see and respond to changes or warning signs quickly, preventing potential accidents.

Even minor slips, trips, and falls can have significant consequences in a manufacturing environment. By ensuring that floors, walkways, and staircases are well-lit, factories can create a safer environment, reducing the risk of accidents and enhancing overall productivity. Proper lighting isn’t just about illuminating the workspace; it’s about giving workers the visibility they need to move, operate machinery, and perform tasks without unnecessary risk.

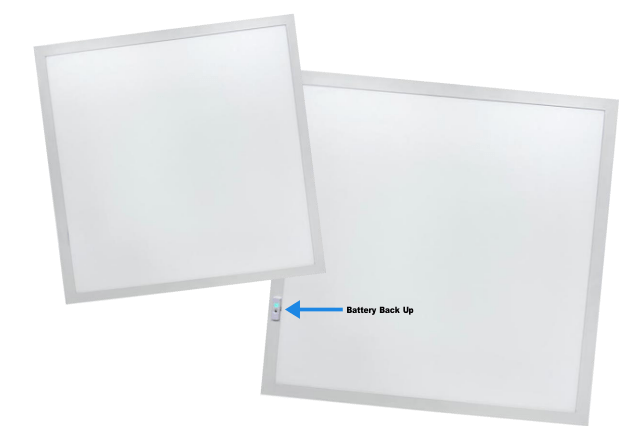

Emergency Situations and Lighting

In the unfortunate event of an emergency, like a power outage or an equipment failure, having a well-lit factory can make a big difference in how quickly and safely workers can exit the area. Emergency lighting, strategically placed throughout a factory, ensures that employees can navigate to exits and that essential safety protocols are followed even when standard lighting systems fail.

Product Quality and Defect Reduction

The Link Between Lighting and Quality Control

Factory lighting can directly impact product quality. In industries that rely heavily on visual inspections—like electronics, automotive, and pharmaceuticals—proper lighting allows workers to identify defects more easily. Good lighting ensures that employees can spot tiny discrepancies that might compromise quality, such as scratches, color inconsistencies, or structural issues.

For example, in a facility that produces painted metal parts, optimal lighting can reveal imperfections in the paint application that may go unnoticed under dim or inconsistent lighting. Identifying these issues early in the production process prevents defective products from reaching customers, reducing waste and boosting customer satisfaction.

Reduced Error Rates and Waste

Poor lighting can lead to higher error rates, which, in turn, create waste and lower productivity. When employees struggle to see what they’re working on, mistakes become more frequent, whether it’s a misaligned part, a measurement error, or a missed defect. By investing in quality lighting, factories can minimize these errors, improving both the quality and consistency of their products. This reduces costs associated with waste and rework, creating a more efficient and productive manufacturing environment.

Energy Efficiency and Cost-Saving Benefits of Modern Lighting Solutions

LED Lighting: The Cost-Efficient Choice

In recent years, LED lighting has become increasingly popular in manufacturing facilities, and for good reason. LEDs consume significantly less energy than traditional lighting options like incandescent or fluorescent lights. This energy efficiency translates directly into cost savings, as lighting typically accounts for a large portion of a factory’s energy consumption.

Beyond energy savings, LED lights are highly durable and have longer lifespans, meaning they require less frequent replacement. Reduced maintenance means fewer disruptions in productivity, and factory managers can allocate those savings to other productivity-boosting initiatives. Moreover, LEDs produce less heat, which can help maintain a cooler and more comfortable factory environment, indirectly improving productivity.

Environmental Impact and Sustainability

Energy-efficient lighting also aligns with sustainability goals, which are becoming increasingly important to both companies and consumers. Many manufacturers are now looking to reduce their environmental footprint, and transitioning to energy-efficient lighting is an easy and effective way to do so. By reducing energy consumption, factories not only save on utility costs but also lower greenhouse gas emissions, making their operations more sustainable.

Choosing the Right Lighting for Different Factory Areas

Tailored Lighting Solutions for Enhanced Productivity

Factories are complex environments, often with distinct zones that serve different purposes—assembly lines, storage areas, quality control, and employee break rooms, to name a few. Each of these areas has unique lighting needs to optimize productivity and safety:

- Assembly Lines: These require bright, focused lighting to ensure workers can see every detail. Task lighting in these areas can help reduce errors and speed up production.

- Storage Areas: Moderate lighting is sufficient, allowing workers to see what they need without consuming unnecessary energy. Automated lighting that activates only when needed is ideal for these spaces.

- Inspection Areas: Quality control zones demand highly accurate lighting to allow workers to identify even the smallest defects. Bright, adjustable lighting works well for these critical inspection tasks.

Tailoring lighting to specific factory areas ensures that each zone is optimally illuminated, enhancing productivity without excessive energy consumption.

Adapting to Future Trends in Factory Lighting

Automation and Smart Lighting

The future of factory lighting is moving towards automation and “smart” systems. Automated lighting systems can adjust based on occupancy, daylight, and even task requirements, ensuring optimal brightness at all times without wasting energy. For instance, automated systems may dim lights in areas where there’s no activity, automatically adjusting when movement is detected. This not only saves energy but also reduces the need for manual adjustments, freeing workers to focus on their tasks.

Additionally, smart lighting can integrate with other factory systems, using sensors to monitor environmental conditions such as humidity or temperature. These integrated systems can enhance safety by providing early warnings if conditions become unsafe, offering an extra layer of protection in high-risk environments.

LED Advancements and Adaptive Lighting Technology

As LED technology advances, manufacturers now have access to adaptive lighting solutions, which can alter color temperatures and intensities based on specific needs or time of day. For example, cooler light in the morning can energize workers, while warmer light later in the day can reduce strain as workers wind down. This adaptability allows factories to maintain an optimal working environment throughout the day, boosting productivity without compromising comfort.

Conclusion: The Power of Effective Factory Lighting

Lighting plays a crucial role in enhancing productivity, quality, and safety in manufacturing environments. With the right lighting setup, factories can create a more comfortable, efficient, and safe workspace, leading to significant improvements in productivity and worker satisfaction. Investing in modern lighting solutions like LEDs and automated systems isn’t just about reducing energy costs—it’s about creating an environment where workers can perform at their best, where quality standards are upheld, and where safety remains a top priority.

Effective factory lighting is more than just a functional requirement; it’s a strategic investment that drives productivity and supports long-term growth. Whether you’re updating an existing facility or designing a new one, consider the impact of lighting on every aspect of your operation—it could be the key to unlocking your factory’s full productivity potential.

Frequently Asked Questions (FAQs)

1. What type of lighting is best suited for factory environments?

LED lighting is generally the best choice for factories due to its energy efficiency, longevity, and adaptability to different task requirements.

2. How can lighting influence worker productivity in manufacturing?

Good lighting reduces eye strain, enhances focus, and minimizes errors, directly boosting productivity by creating a more comfortable and efficient workspace.

3. What are the safety benefits of proper lighting in factories?

Proper lighting helps prevent accidents by making hazards more visible, especially in areas with heavy machinery or moving equipment, thereby enhancing overall safety.

4. Can modern lighting solutions reduce operational costs in manufacturing?

Yes, energy-efficient options like LEDs reduce electricity usage, while automation can minimize unnecessary lighting, significantly lowering energy bills and maintenance costs.

5. How does lighting affect product quality in a manufacturing setting?

Quality lighting helps workers identify defects more easily, ensuring high standards in product quality by allowing quick detection of inconsistencies before they reach customers.